Metolachlor is a chlorinated organic herbicide that was used for the weeding of maize and, occasionally, sunflower. Metolachlor and the metabolites ESA and OXA are present in the water resources in a large part of western France, despite having been banned in France since 2003. They are replaced by S-metolachlore which leads to the same metabolites ESA and OXA. Throughout the year, the products are found at concentrations sometimes exceeding μg/l.

Jacobi offers different options to ensure drinking water plant operators comply with the regulation regarding maximum pesticides concentrations in drinking water (concentration <0.1 μg/L per individual molecule). These options are:

- Efficient powder and granular activated carbons that can be used in combination. They are available in a ready to use form which makes their operation easier.

- ACS (Attestation de Conformité Sanitaire) compliant mobile adsorbers filled with granular activated carbon (GAC), and all related services, to limit CAPEX needs and allow for immediate treatment so as to protect consumers’

Jacobi’s experienced application engineering team assist drinking water operators in their choice of product and method of use for different activated carbon products. This means they are sure to achieve the optimum treatment outcome required as economically as possible.

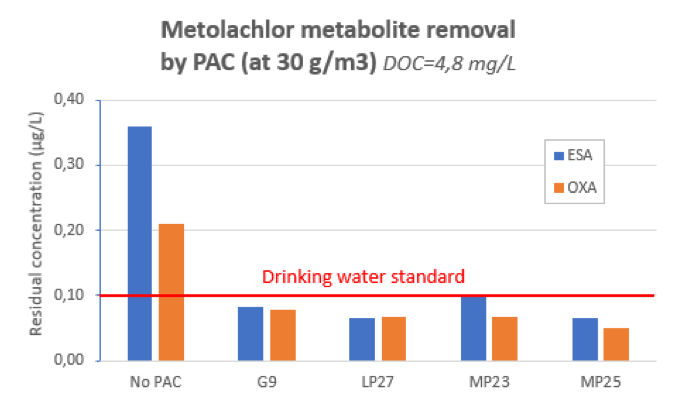

Powder Activated Carbon (PAC)

Powder activated carbon (PAC) is a flexible and adaptable solution which is easy to implement, therefore, it is used in drinking water production for seasonal or short to medium term problem solving. Various studies with different powder activated carbon grades from the Jacobi AquaSorb™ range showed good removal of metolachlor to below the drinking water standard of maximum 0.1 ppb.

(Figure 1: Metolachlor removal test results with PAC)

Aquasorb™ powders are delivered in small sacks, bulk bag and bulk tankers or, alternatively, as a ready to use stable liquid suspension (HYDROSOL™), for safe, clean and immediate treatment in plants not equipped with powder handling equipment.

Granular Activated Carbon (GAC)

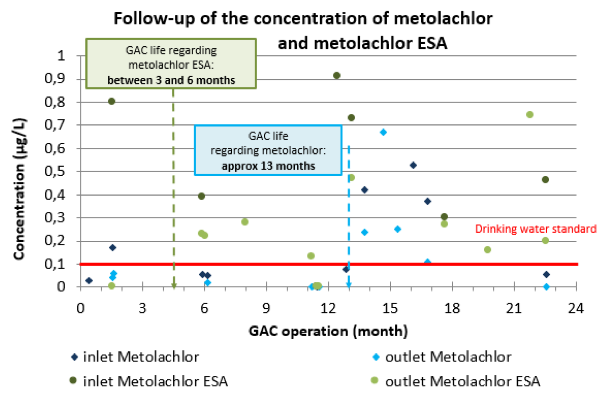

Granular Activated Carbon (GAC) is mainly used in open gravity filters or in mobile and fixed pressure absorbers. GAC is usually the preferred way to remove persistent pesticides when continuous treatment is required. Once the granular activated carbon is saturated, or when breakthrough occurs, it can be recycled by thermal reactivation in one of the Jacobi regeneration plants.

Jacobi offers ready to use products (wet and neutralised), so as to limit time and water consumption necessary for GAC commissioning and start up.

The field experience, as illustrated in Figure 2, confirmed that granular activated carbon can adsorb the metabolites of metolachlor to below the French drinking water limit. The breakthrough of the metabolites occurs while the activated carbon still has adsorption capacity for other molecules (e.g. S-metolachlor).

(Figure 2: Metolachlor removal test results with GAC)

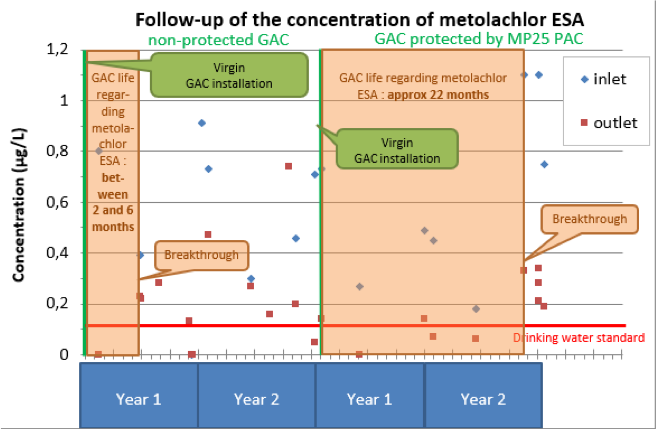

Some municipal drinking water plants have chosen to protect the granular activated carbon by dosing powder carbon upfront in order to reduce the activated carbon consumption. The field experience, illustrated in Figure 3, shows the lifespan of the same granular activated carbon (same nature, volume and operating conditions) in operation alone and when protected by powder activated carbon.

(Figure 3: GAC protection with PAC)

Thus, the protection of GAC by an effective PAC upstream, can extend the GAC life from 3-6 months (without protection) to almost 22 months (with protection) – a lifetime of at least 4 times longer.

Mobile Adsorption Systems

Jacobi’s mobile filter units AquaFlow™ V20 H have been installed on several ground water treatment plants in France using granular activated type AquaSorb™. The units have the French Health Compliance ACS (Attestation de Conformité Sanitaire) approval for use in potable water applications.

(Picture1: AquaFlow™ V20 H next to the pumping station)

The Jacobi Mobile Filtration Units AquaFlow™ V20 H are designed to treat up to 80m³/h and can be used in parallel in cases of higher flowrates, as shown in picture 2.

(Picture 2: AquaFlow™ V20 H mobile filters in parallel operation)

Once the activated carbon is spent with another mobile adsorber, Jacobi will exchange the complete drained mobile adsorber, including carbon, with new or regenerated product using specially designed trucks. Jacobi provides the full change-out services, including filter replacement when GAC is saturated, and reactivation of spent GAC.

For more information on this application please visit out contact page to find the correct Jacobi regions contact information or fill in the form below and one of the team will be in touch.