Introduction

In many industrial operations, the products produced in campaigns vary greatly in their composition. This is common in waste management companies, chemical and pharmaceutical production sites, as examples. These campaigns often change because of different input streams, smaller but different production lots, as well as frequent contract manufacturing. This may also lead to fluctuating flowrates and concentrations of organics and inorganics in the wastewater. Changing environmental legislation can also be a challenge with which to comply. To avoid incurring discharge prohibitions to the local wastewater system, intelligent wastewater treatment systems have become more and more important.

A waste handling, disposal, and recycling company for hazardous waste

A company, located in Southern Germany, operates its own chemical and physical wastewater treatment plant. The treated water is finally discharged into a public wastewater system. After a number of cases of exceeding permitted limit values for heavy metals, (especially nickel and residual organics), the local authorities instructed the generator of this waste stream to install an intermediate treatment stage. The limits that were required for complaint discharge, effective from January 1st, 2019, are as follows:

Inorganic impurity

- Nickel (main issue): < 1mg/l

Organic impurities

- Benzene, Toluene, Ethylbenzene, Xylenes (BTEX): < 1 mg/l

- Adsorbable Organic Halogens (AOX): < 1 mg/l

A ban on future discharges was threatened if the limit values were exceeded again.

How to remove inorganics like Nickel and organics from wastewater?

Residual organics

To reduce the residual organic impurities like BTEX, AOX and petroleum hydrocarbons (PHC) below the limits set by the local authority, Jacobi Services proposed a granular activated carbon (GAC) AquaSorb™CS.

Nickel

To remove Nickel and other heavy metals from wastewater, a chelating ion exchange resin was considered necessary. Due to the high selectivity for nickel, Jacobi Services recommended the usage of the chelating resin, type Resinex™ CH-23. This resin exhibits a very high efficiency in nickel removal in the cationic, elementary form (Ni²⁺). As an order of magnitude, the average removal capacity of Resinex™ CH-23 is in the range of 20g of Ni²⁺ per liter resin. Resinex™ CH-23 also efficiently removes cadmium, cobalt, copper and lead in their elementary cationic form.

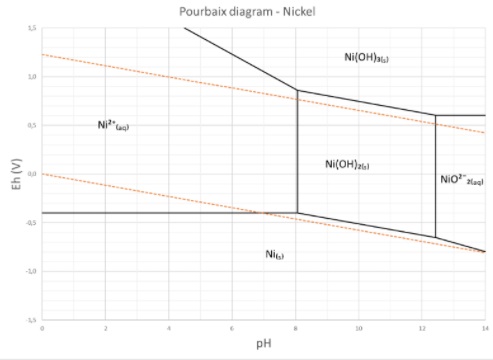

To remove Ni²⁺ effectively, a pH value of 2 – 4 is needed (see the Pourbaix diagram in Figure 1). In addition, suspended solids > 50 µm should be removed beforehand.

The wastewater, coming from the customer’s own physico-chemical treatment plant, was adjusted to a pH value of about 3. To remove suspended solids > 50 µm a pre-treatment with filter gravel or filter anthracite was recommended.

Jacobi’s industrial Mobile Filter Units (MFU) on a rental base – easy to handle, ex stock available, no capex needed.

Together with the customer Jacobi Services developed and installed a complex wastewater treatment system, comprising of 3 mobile filters AquaFlow™ 2000 arranged in series; each in combination with a 2 m³ buffer tank and a pump, as essential part of the following pre-conditioning, pre-treatment and cleaning steps:

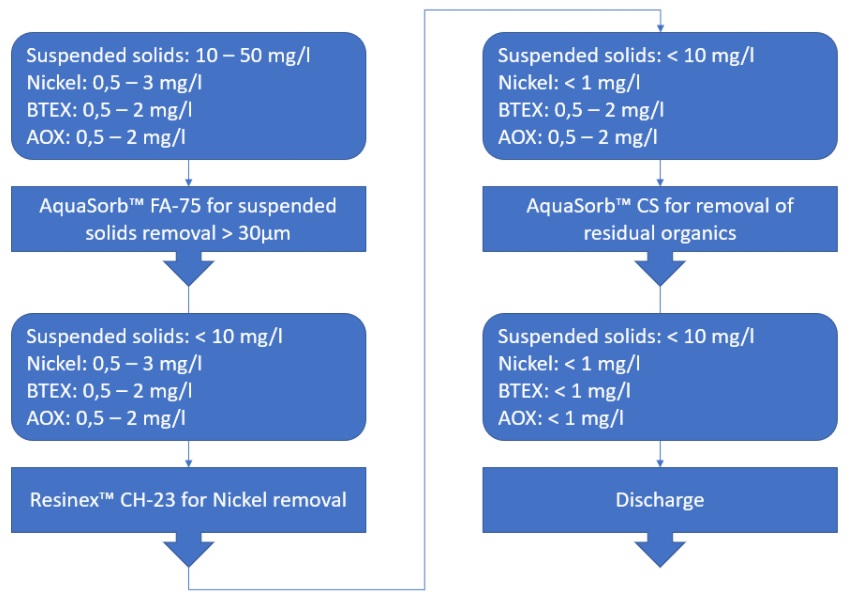

Figure 1: The process flow diagram of the wastewater treatment system

Step 1: Adjusting the pH value (by the customer)

Step 2 (1st AquaFlow™ 2000): Filter anthracite AquaSorb™ FA-75 to remove suspended solids (by Jacobi Services)

Step 3: (2nd AquaFlow™ 2000): Resinex™ CH-23, to remove Nickel in its elementary (Ni²⁺) form (by Jacobi Services)

Step 4 (3rd AquaFlow™ 2000): AquaSorb™ CS, to remove residual organics (by Jacobi Services)

Step 5: UV-system for sterilization (by the customer)

For the purposes of assessment by the authorities, the water is then transferred to an outdoor basin (40m³) before being discharged into the local wastewater treatment system.

Executive summary

In cooperation with the customer it took us less than six weeks to install a complex wastewater treatment system with AquaSorb™ FA-75, Resinex™ ion exchange resin, and AquaSorb™ CS activated carbon in combination with AquaFlow™ mobile filter units on a rental base. By meeting the limit values for discharging the wastewater into the public wastewater system the customer secured his operating permission.