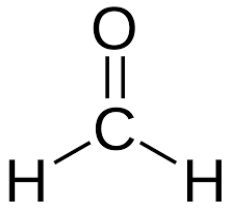

Formaldehyde, IUPAC name methanal, is the simplest aldehyde, with the formula, CH₂O. Its structure is shown in Figure 1. It occurs naturally but is toxic and highly volatile.

Figure 1: Structure of formaldehyde

Removal of formaldehyde is complex as it can adopt many forms. In its simplest form, formaldehyde is a gas. It is skin-irritating and exhibits a pungent odour, even at concentrations less than 1 ppm. The odour threshold is between 0.5-1.0 ppm. Formaldehyde vapours are also flammable and explosive.

Naturally occurring formaldehyde is found in food (especially in fruit) at very low levels, is also created through the combustion of tobacco (smoking) and occurs in human metabolism, where it is broken down via enzyme catalysis to carbon dioxide and formate, and removed by exhalation and urination respectively.

The industrial use of formaldehyde

There are many industrial uses for formaldehyde, namely in the synthesis of inks, as resin binder in the manufacture of furniture (plywood, composite panels) and furnishings (carpets), and as a preservative in chemical synthesis within pharmaceutical production (vaccines) and the chemical industries (cosmetics, shampoos, deodorants and soaps). The most widely recognised use of formaldehyde is in the preservation of lab specimens and embalming in mortuaries.

Formaldehyde in the environment and its effects on human health

Environmental concerns are limited, as formaldehyde is rapidly degraded in the atmosphere by reactions with other substances or in the soil by bacteria. The risks to humans are much greater because formaldehyde is easily absorbed through the skin and respiratory tract. It is assumed that Sick Building Syndrome is caused by formaldehyde outgassing and can lead to a variety of symptoms such as nausea, headaches, fatigue, lack of concentration, shortness of breath, irritation of the eyes and throat, and a blocked or runny nose.

Our solutions

The Jacobi Group have developed the AddSorb™ VF1 range of activated carbon products especially designed to efficiently remove formaldehyde and fix it to the activated carbon surface. This sustainably manufactured product is based on coconut shell raw material. The manufacturing process of this material involves the carefully controlled addition of a highly reactive proprietary impregnation to the internal surface. This ensures the efficient removal and retention of formaldehyde while retaining an excellent physical adsorption capacity. The resulting chemical complex is not volatile under standard operating conditions and is firmly affixed to the activated carbon. AddSorb™ VF1 can be supplied in a range of granular particle size distributions and pellet diameters to suit all pressure loss and processing requirements.

The Jacobi Group also offers a range of EcoFlow™ mobile filters for efficient use of AddSorb™ VF1.

It is always recommended to contact our technical experts for sizing of a formaldehyde removal system.

1 Comment