Introduction

A common practice in chemical or pharmaceutical plants is to collect VOC (volatile organic compounds) laden air or gas streams and treat them in one central place. for example, in a thermal combustion unit. Thermal combustion units need maintenance or, in the event of sudden breakdown, replacement by an alternative technology. Mobile filters with activated carbon are the solution for VOC reduction in case of maintenance work or failure of the air treatment equipment.

A pharmaceutical company producing API

In 2019, just before the annual shut-down period, there was an explosion in a thermal combustion unit from a pharmaceutical manufacturing facility that threatened to shut down the plant completely, causing major losses for the company:

- They had to cancel and delay orders.

- The work force of 160 people became temporary unemployed.

- They faced potential risks of consequential damage claims for not fulfilling existing contracts.

Not shutting down the plant would lead to complaints from their neighbours, environmental and legal issues and, finally, to huge financial penalties. A classic dilemma.

Jacobi Services was contacted and selected as the activated carbon partner with in-house capabilities to offer mobile filters as a comprehensive solution. Jacobi Services, as the general contractor, managed the solution from process design up to start-up. Jacobi also arranged a partnership with a local OEM for the erection of the required piping and auxiliary equipment. The subcontractor dealt with the erection of the plant using local workers that had the necessary certifications to work on site and that also spoke the local language.

The gas treatment project

The gas treatment plant was working under the following conditions:

- Flow Rate: 250m³/h 24h/day

- Ambient operating temperature

- Dry relative humidity

- VOC inlet concentration 1.2g/m³ with several organic impurities

- Acetonitrile

- Ethyl acetate

- Toluene

- Tetrahydrofuran (THF)

- Dichloromethane (DCM or methylene chloride)

- Acetone

- Methanol

- Heptane

The required treatment objective was maximum 40mg VOC/m³ at the outlet and 25mg DCM/m³. Jacobi Services began to proceed in systematic process steps.

Safety first

Safety first is something the Jacobi Services engineers take care of, so together with the customer, it was decided to include the following in the concept:

- A fan to add dilution air in order to reduce the organic concentration to below 25% of the Lower Explosion Limit (LEL).

- Carbon monoxide detection to detect the development of any hot spots.

- Fire damper before and after every filter (adding the ability to separate and isolate the filter).

- Nitrogen (N₂) injection in the event of a hot spot detection.

- A control panel to be able to check online and act remotely if necessary.

- A signal to be sent to the control room so that operators could monitor the installation.

- Two EcoFlow™ C18 H filled with EcoSorb™ GXB in a carousel arrangement to provide a 100% continuous solution.

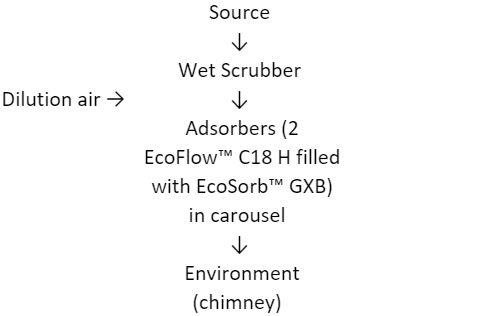

In addition to the aforementioned safety provisions, it was also decided to install a wet scrubber in order to remove the water soluble (and less well adsorbed) impurities prior to the adsorbers.

Figure 1: Gas treatment flow sheet.

The Jacobi Services team, together with the local subcontractor, was able to start up the new plant within 2 months after the first contact. The customer was very satisfied and commented: “We are really pleased that we could start up our plant so quickly, with this fully automated compact and robust solution. Our production is now running at full capacity to recover lost production time while respecting all the local environmental requirements in a safe way.”

It is estimated that the system will be running for nine to twelve months, until the new combustion unit is installed and commissioned.