APPLICATIONS & SOLUTIONS

The key objectives for food companies are product safety and continuous quality. Unwanted tastes and colours must be dealt with, and impurities need to be effectively removed. Public health and safety issues are at the top of the agenda.

Jacobi Services purification solutions are used to:

- Demineralise liquid streams

- Improve the colour stability

- Increase the crystallisation yield

- Reduce odour

- Remove colour

- Remove toxic compounds such as polycyclic aromatic hydrocarbons (PAH); dioxins from vegetable and fish oil

Jacobi Services offers customised packages with immediate availability to meet all these purification challenges. On top of this, we have developed a collection of top-of-the-range adsorption products that maximise performance and keep costs to a minimum.

SUMMARY

- Clean solution, operators do not come into contact with the activated carbon

- Custom reactivation or take back and supply of virgin carbon is possible

- Mobile filters are a proven technology used in a wide range of applications

- On-site representative piloting

- Product recovery is efficient with granular activated carbon

Vegetable Oil

Raw materials to produce refined vegetable oil need to be purified because they are sometimes contaminated with pesticides and herbicides. Some raw materials are also directly dried with engine off gas resulting in polycyclic aromatic hydrocarbons (PAH) contamination. For example, contamination with benzo(a)pyrene.

Fish Oil

Fish and sea mammals are generally at the top of the marine life food chain and accumulate carcinogenic persistent organic pollutants (POP) such as dioxins, furans, polychlorinated biphenyls (PCB), pesticides and herbicides, etc. as a result of human activity. Fish oil can be purified with the Jacobi Services purification solutions.

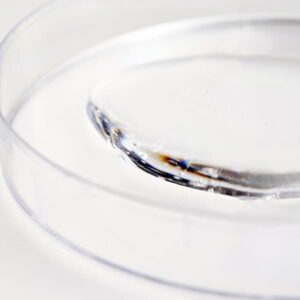

Liquid Sugar Solutions

A very common application of both activated carbon and resins is the purification of various sweeteners. This includes sucrose (from cane and beet), glucose and fructose syrups from starch or inulin, which are used to produce food, sweets, and soft drinks. It is often necessary to remove colour, taste, and odour constituents as well as contaminants.

Lactate Purification

Lactates are produced from lactic acid by adding an alkaline to a lactic acid solution. This results in a exothermic acid-alkaline reaction and will increase the temperature of the solution. Colour can then be formed as a result of the temperature increase and is removed by using mobile filters with activated carbon.

GET IN TOUCH

Fill out the short form below and our team will be in touch.

*indicates a mandatory field.